Current Projects

Comet II Battery Box Ambient Temperature Sensor

This is the 2nd Comet II battery box temperature

sensor which reads ambient temperature in the

battery box to control the cycling of the battery

charger. When the ambient temperature eceeds

65 degress C, the charge shuts off until the

sensor read under 55 dgrees C. We had to cut the

sample batter lug sensor apart to find a tiny circuit

board with a very old AD temperature transducer and

zener diode potted in epoxy. We duplictaed the board,

found the original OEM battery lugs and the original

Rail rated control cable to assemble the prototype.

It was installed and is being evalautaed for 6 months.

There are about 200 Rail Cars affected.

Comet II Rail Car Battery Charger BHTD Temperature Sensor

One of our local Commuter Rail customers, who we have done extensive work for. had

approached us with a request to reverse engineer and fabricate a battery charger temperature

sensor for their 74 VDC battery bank on their Comet II passenger rail cars. We delivered th first

prototype in November, and after 6 months of testing, they placed an order for 8 initial production

sensors. There are over 150 affected rail cars in this fleet. Veritech Part number is VT350001

UPDATE ! As of March 2025, they have order 32 of these sensors

Windshield Wiper Motor Replacement Solution for Large Canadian Transit Agency

A few months back, we were contacted by one our coolant level sensor

customers in Vancouver, Canada about failures of the wiper motors on

their transit buses. Because of the rainy and misty Pacific Northwest climate, the

wipers are operating a large percentage of the time and the current motors will stall

or operate intermittently. We found what we believe to be a better quality motor from

a US manufacturer of wiper equipment and after some adapting for harnessing and linkage,

the first motor is being evaluated on one of thier buses. The plan is to move forward in

the Fall with a 10 bus, 20 motor pilot study to better evaluate the new replacement.

UPDATE: January 2023 Our Canadian distrubutor NATSCO placed an order for 10 sets (20 motors and acccesories) for the evaluation on 10 New Flyer buses.

New Solenoid Valve for Transit Bus Brake Pressure Interlock

One of our great early adopter transit agency customers who has our coolant level sensors and brake pressure switches installed on their Gillig buses, contacted us about an issue they were having with the Brake Interlock Solenoid Valve. There are two of these in each bus, one for the front brake operator interlock and one for the rear. On some buses traveling on routes with frequent stops, the solenoid valve is activated at every stop to release the interlock. The coils on some of these valves have been overheating which leads to the interlock remaining on. The bus then has to be towed in because it cannot move with the now stuck interlock. We have identified the root cause of these failures and will be having new stainless steel valves with higher temperature components fabricated in the next few months. We will send two of the new solenoid valves to our customer in Florida for evaluation and if all goes well, they will be campaigning their affected fleet. If your agency is experiencing stuck interlock conditions due to failing solenoid valves, please let us know and we can include you in our evaluations

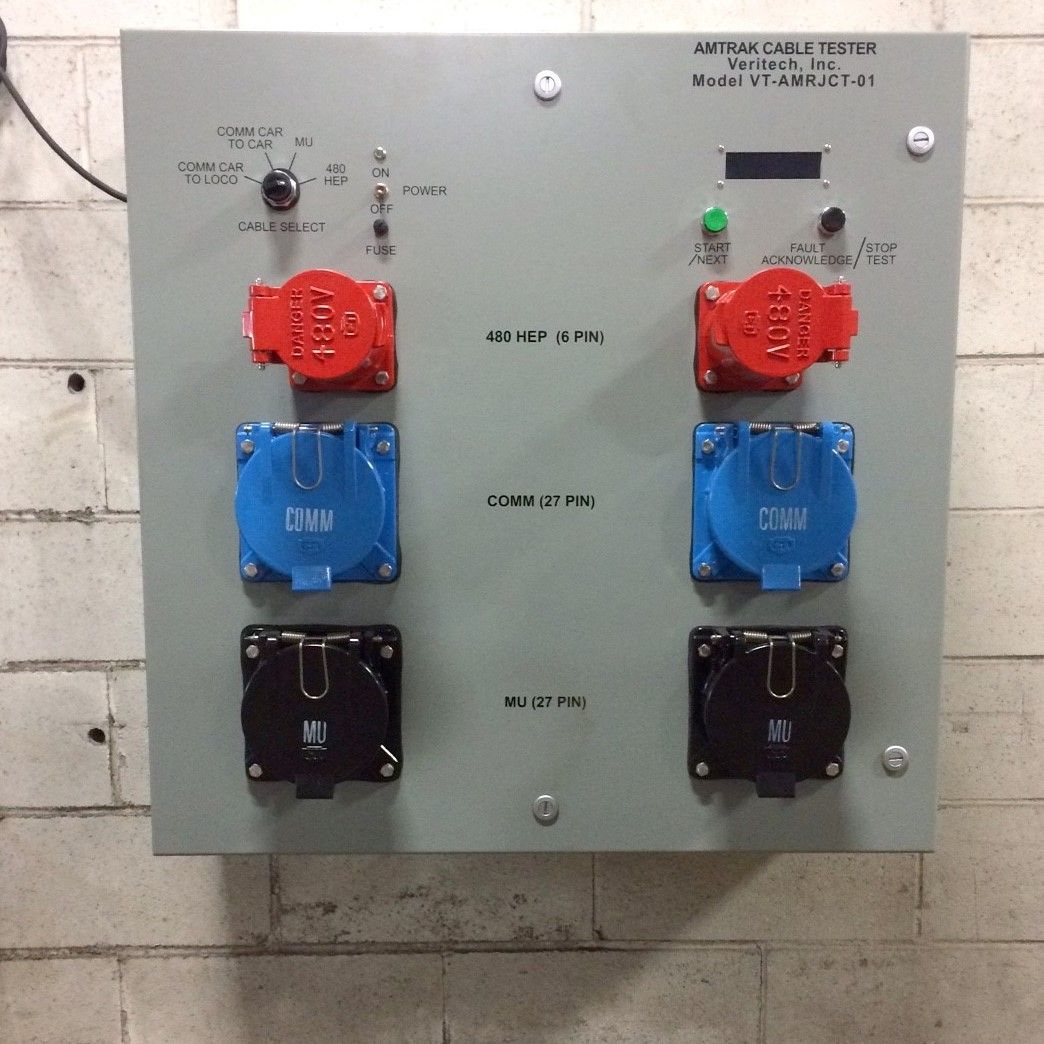

AMTRAK Automatic Rail Jumper Cable Tester

After seeing our Semi-automatic Rail Jumper Cable Tester at a New Jersey Transit location, an electrical engineer for locomotives contacted Veritranz by Veritech about the possibility of us developing a custom unit for AMTRAK initially for their Sunnyside Yards location.

He wanted a fully automated unit for continuity, shorts and current breakage along with an integrated high voltage section for testing insulation resistance (Hi Pot) on the cables. The final design allowed complete testing of a 27 pin jumper in about a minute and testing of the 480 HEP cables in less than two minutes.

With no set up time required along with fast testing speed and ease of use, our device was very well received by the AMTRAK maintenance employees and we recently received an order for their fourth unit to date. It has dramatically reduced trainline failures on AMTRAK’s equipment by quickly and efficiently weeding out bad jumper cables.

Heavy Duty Transit Bus Coolant Surge Tank

In the Spring of 2019, we were referred to a large Midwest transit agency by one of our OEM customer representatives for help with their coolant surge tank issues on their transit buses. It seems they had experienced an extremely high failure rate on some OEM surge tanks for many years which required constant welding and repair to keep in service.

These failures were very costly for the agency due to the extensive person hours required to remove, repair and reinstall the tanks. They were looking for a much more robust, drop-in replacement tank to be designed and manufactured. They had requested a 3X safety factor meaning that the tanks needed to be able to contain a nominal temporary pressure of 30 Psi. After extensive analysis of the OEM tank, we set about designing a new tank which could conceivably last the life of the bus and exceed all customer expectations. Five prototype tanks were produced and are undergoing an extensive evaluation at the customer agency conducting the evaluation. Please let us know if you are interested in this product for your own buses.

Coolant Level Sensor Replacement for 4 Pin Capacitance Type Sensor

In December of 2019, one of our transit agency bus maintenance engineers contacted us about failures of a 4 pin capacitance type coolant level sensor installed on his 2018 transit buses. While the agency has many of our stainless steel coolant level sensors and hydraulic level sensors successfully installed on their buses, they have had enough coolant related issues to warrant testing of the sensors during PM.

He was alarmed to find that many of the capacitance sensors they tested failed in the opposite mode of the previous plastic sensors which gave a false positive error code to the ECM. These sensors, however, failed to send an error code in the absence of coolant, exhibiting a false negative mode of failure. This mode of failure could lead to a potentially destructive overheat condition with the transit bus engine. Our stainless steel float style replacement is the VT220594-FZ pictured on the right.

New Custom 36 position Rail Jumper Cable Tester for Long Island Railroad

We have adapted our AMTRAK cable tester design to add 9 positions to build a new Custom unit for Long Island Railroad (LIRR). Unlike most other railroads, they employ 36 postion jumpers for the MU and COMM jumper cables. They also require some shield testing for certail sets of wires. This unit will be built and deleivered most likely in September.

Latest Update on this project : We delivered a fully operational 36 poition Rail Jumper Cable

Tester to Long Island Railroad in December 2022 and it has been evaluated and installed.

The device is working very well and should siginifcantly reduce trainline failures in their fleet.

KEOLIS purchases and VeriTranz delivers their first Rail Jumper Cable Tester

Keolis NA, who maintains and operates the Massachusetts Bay Commuter Rail for MBTA in Boston

has purchased one of our AMTRAK style testers to test their jumper cables and reduce trainline

failures. This was our first tester with an alternate style conector for the 480 Head End Power

connector. This unit should be installed at the Somerville Engine Terminal (Big Blue) very soon.

UPDATE : Oct. 2023, Keolis has placed another PO with us for two more cable testers.

Your Transit Agency's ( Fill in Name ) Next Failing Component (Fill in part) Issue

Since our first stainless steel float switch replacement for a failing plastic upper

coolant level float switch on NABI buses over 7 years ago,VeriTranz by Veritech

has been helping transit agencies with their OEM bus component issues and helping

to reduce road calls and the labor costs of constant replacement of less than satisfactory

components. If you are seeing failures of a particular part and getting little or no help from

the OEM to solve the issue, let us get to work for you and keep your buses where they belong . . .

ON THE ROAD ! !

SEPTA Rail Scanner Pro build for 6 more units

SEPTA in Philadelphia has ordered 6 more of our Scanning Audio Frequency Rail Current Detectors

(Rail Scanner Pro) to supplement the Norristown HighSpeed Line extension. This will bring the

agency to a total of 29 units between Subway, Light Rail, Commuter Rail and the High speed Rail.

SEPTA also has more of our coolant level and oil pressure sensors installed on their bus fleet than

any other agency in North America.